- Product introduction

main feature:

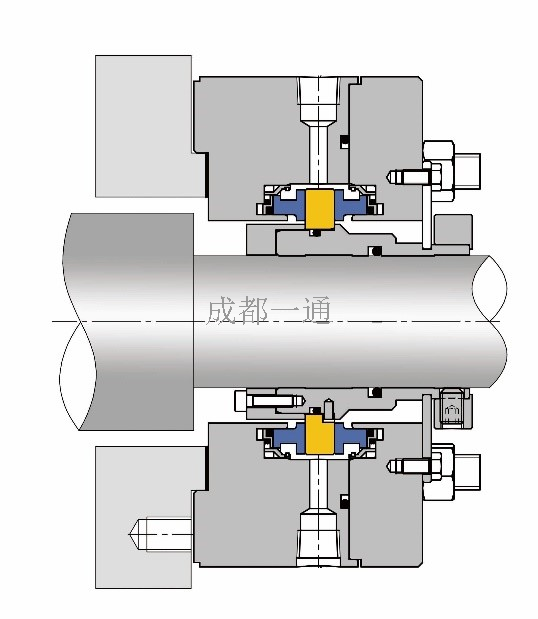

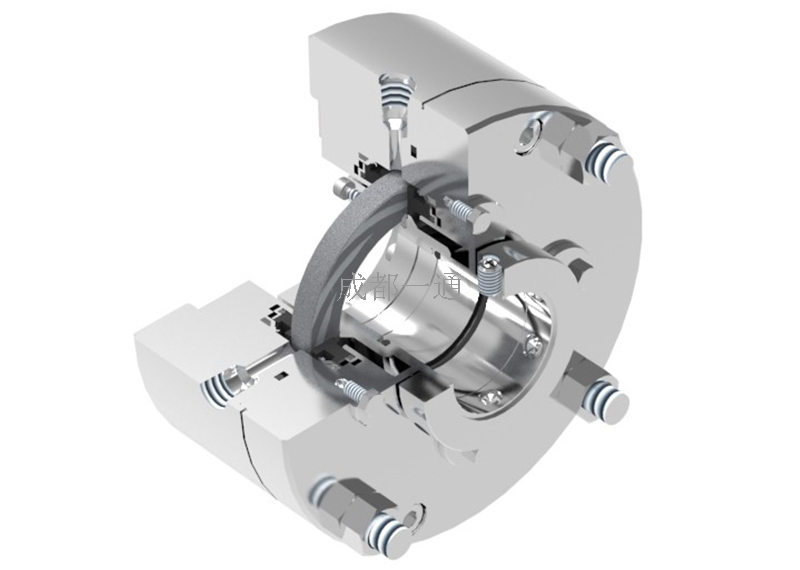

Composed of two static ring components and a moving ring, the axial size is compact, which is more suitable for occasions with narrow axial space or high speed. The principle of "gas blocking" is used instead of "liquid blocking", and the medium is sealed with a sealing gas with a pressure higher than the pressure of the sealed chamber by 0.2 ~ 0.3Mpa to ensure that the process medium achieves zero escape to the environment, meets VOC emission requirements, and is safe and environmentally friendly.

A small amount of sealing gas has entered the process. The seal has high requirements on the pressure of the sealed air source. It must be higher than the pump cavity pressure at any time without interruption.

The seal adopts cartridge type, convenient installation and disassembly, non-contact operation, energy saving, safety and environmental protection, reliable performance, simple operation, and an average service life of up to 3 years. .

Using parameters:

Pressure: 0 ~ 1.6MPa

Temperature: -104 ~ 260 ℃

Speed: ≤3600r / min

Applicable working conditions:

Applicable working conditions: Suitable for various fluid media, mainly used for toxic and harmful, high temperature, easy coking, easy self-aggregation, strong corrosive, granular media, etc. Such as H2S fluid media, solvents, benzene, quench oil, tar, methanol, etc.