- Product introduction

main feature:

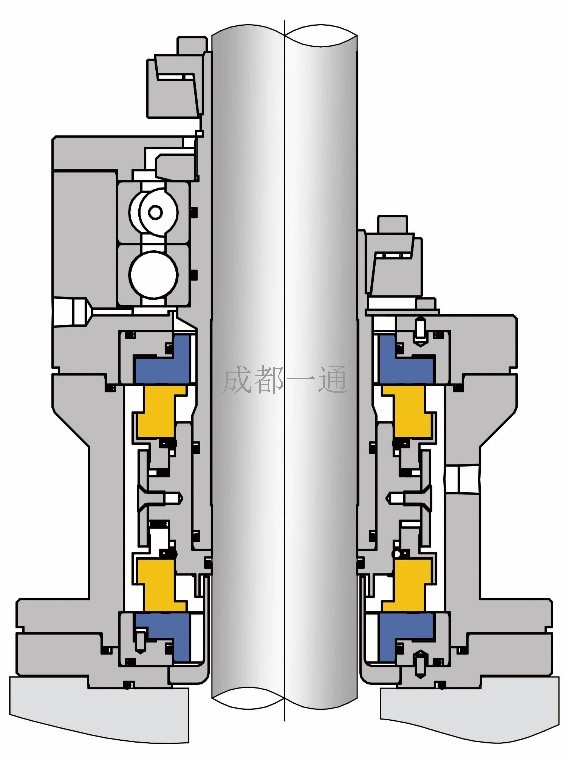

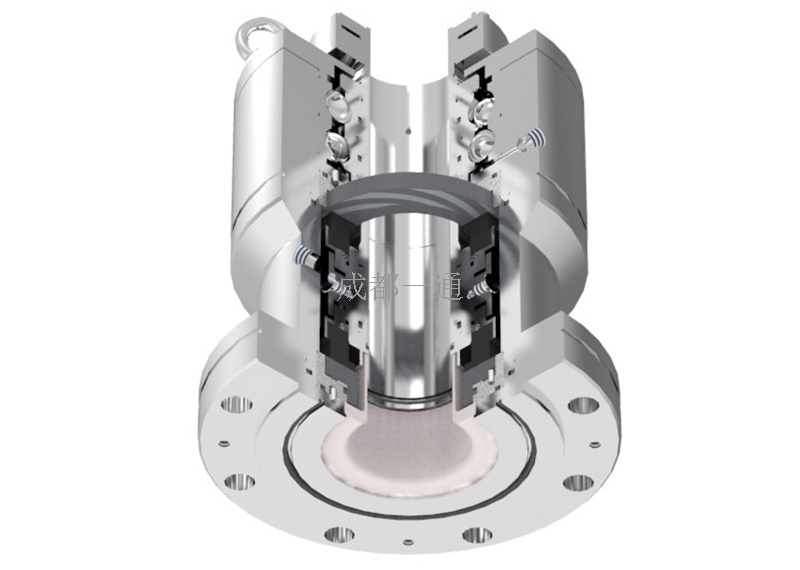

Double-end structure adopts the principle of "gas blocking" instead of "liquid blocking". The medium is sealed with a sealing gas that is 0.2 ~ 0.3Mpa higher than the pressure in the kettle to ensure that the process medium achieves zero escape to the environment and meets VOC emission requirements. Safety and environmental protection. The seal has high requirements on the pressure of the sealed gas source. It must be higher than the pressure in the kettle at any time without interruption.

With or without bearing can be selected according to needs; static ring adopts L-shaped fixed structure with small end face deformation; special floating ring structure design to avoid the failure of the seal ring; seal design has "drainage device" (optional) to reduce Risk of contamination of the medium due to seal failure; choose materials that meet the FDA certification for contact with the medium, which can be used in the food and pharmaceutical industry; according to food and pharmaceutical sterilization requirements, special sterilization and disinfection channels can be designed to sterilize the sealed cavity and the interior of the device operating;

The seal adopts the cartridge type, which is convenient to install and disassemble, and is suitable for upward stirring work. Sealed non-contact operation, energy saving, safety and environmental protection, reliable performance, simple operation and maintenance-free, with an average service life of about 2 to 3 years.

Using parameters:

Pressure: 0 ~ 1.4MPaG

Temperature: -40 ~ 200 ℃

Speed: ≤10m / s

Applicable working conditions:

Suitable for all kinds of gas-liquid media that allow a small amount of sealed gas